SERVICE PROCESS

Professional design capability

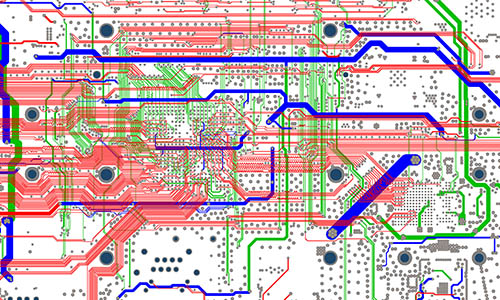

STEP1 PCB LAYOUT

1.Net in

Layout Guide Check / Impedance Check / Power Voltage Check / Power Current Check / Package Check / Net in Check

2.Placement

Mechanical Check / Placement Check

3.Routing

Routing Check / DRC Check / Text Check

4.Gerber Out

Gerber Final Check

STEP2 PCB Sample Mass Production

Printed Circuit Board (PCB) / Aluminum Substrate / FPC / Soft & Rigid PCB, Sample / Small Lot/Mass Production; Maintain stable quality and cost.

STEP3 Parts Purchasing and Material Preparation

In order to ensure smooth inquiry process of the BOM table, please provide complete material number, packaging, and quantity. If there is a brand requirement, please specify. We can provide material preparation for both mass production and small-quantity samples.

STEP4 PCB ASSEMBLE

Regardless of sample/small lot/mass production, we have diversified supply chain and material quality control with prompt delivery.